Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Kiln Engineering Co., Ltd. were established in February 2006 and January 2014 respectively. Is a professional company engaged in glass factory (kiln) design, kiln (equipment) construction and installation and glass production technical services. The company mainly serves the glass factory design of flat glass, photovoltaic calendered glass, electric light source glass, daily-use glass, water glass and ceramic frit production lines, glass engineering installation and construction, firing and baking kiln, commissioning and related technical training, technical services, and professional companies for hot and cold repair of glass kilns.

1. Oxy-combustion Technology of Glass Melting Furnace Oxy-combustion technology is a technology with obvious energy saving and environmental protection effects. At present, only three large-scale float glass melting furnaces in the world have adopted oxy-combustion technology, but its application in domestic float glass production lines is still blank. There is no need to change the fire and the regenerator structure in the air-assisted furnace using the oxy-fuel combustion technology. Oxy-combustion technology can greatly reduce the energy consumption and waste gas emission in the production process and improve the quality of glass. Take a 500t/d float glass melting furnace as an example, and its emission reduction effect is shown in Table 4. Now, the attraction of this technology is increasing with the continuous reduction of oxygen cost and the continuous increase of energy cost. It is believed that this technology will be popularized and applied in domestic float glass production lines in the near future.

2. —— The amount of waste gas in the glass furnace with full oxygen combustion is less than that in the air-assisted furnace, and the flue gas temperature is higher, which can be used to generate steam, preheat batch or broken glass, generate electricity by heat, prepare oxygen needed for full oxygen combustion or preheat oxygen and combustion gas. From the results of a large number of laboratory studies that have been carried out at present, it is more obvious to preheat the batch directly by using the high temperature exhaust gas of the all-oxygen combustion kiln. The batch can be preheated to 510℃ by using the high-temperature exhaust gas from the oxy-fuel combustion kiln, and the energy consumption can be reduced by 37% compared with the traditional air combustion-supporting process. Higher and higher energy costs make it more and more valuable to invest in this technology.

3. New melting and clarification technology

Theoretically, the formation temperature of molten glass is only 1450℃. Usually, the highest melting temperature of float glass furnace reaches 1580 ~ 1600℃, mainly for high-temperature clarification to eliminate bubbles in molten glass. By adopting decompression clarification technology, the melting and clarification functions of the melting part of the traditional glass melting furnace are completely separated through the change of furnace structure, that is, the melting and clarification functions of glass are completely separated, which can reduce the melting temperature, save energy, effectively eliminate bubbles and improve the melting quality of glass melt. After defoaming under reduced pressure, the number of microbubbles can be reduced to 0.2 /kg glass liquid; It can also reduce the melting and clarification temperature by 150℃, so it can not only save 30% of the fuel needed for melting and clarification, but also reduce the emission of nitrogen oxides, which is beneficial to environmental protection and prolong the service life of the furnace. Foreign research has made some progress and achieved success in industrial experiments. This is a forward-looking and very promising technology, which will definitely bring a major breakthrough to the glass melting technology.

4. The research of bubbling combustion technology aims at strengthening the circulation of molten glass, promoting the clarification and homogenization of molten glass without wasting energy.

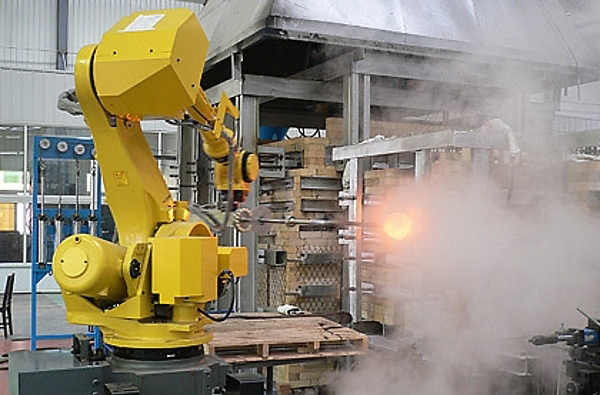

The solution to the problem is to inject combustible gas from the bottom of the melting furnace, which can stir the glass melt when it rises in the glass melt.

When the gas reaches the surface of the molten glass, it reacts with the remaining oxygen in the kiln and burns in a high temperature atmosphere, which in turn heats the glass.

Glass liquid surface. That is, it plays the role of stirring and heating at the same time, which not only reduces energy consumption, but also shortens the heating time.

5. Convection melting technology Glass is heated in a furnace, mainly by radiation and partly by convection. In convective melting, a or

Several spray guns are installed on the crown, and the flame reaches the melt surface vertically downward. This convection can promote heat transfer.

Loss and energy saving. This technology has been installed in several experimental furnaces, and it can also be used as an innovative way of melting furnace.

Convection melting can also be used in the furnace reconstruction.

6. Research on new glass composition to improve quality through research and development.

The professional technicians of Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Kiln Engineering Co., Ltd. focused on the design and production technology of float glass, flat-drawn (lattice) glass, calendered glass and photovoltaic calendered glass production lines, and carried out bold innovation and transformation from 60t/d to 600t/d, from marten flame and transverse flame furnaces. In recent years, cold repair, baking, thermal insulation and hot repair of large-scale float and rolled glass furnaces are the main projects of the company.

Proprietary technologies of Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Kiln Engineering Co., Ltd.: energy-saving kiln design technology, kiln cold repair breast wall hanging hook brick top replacement, large crown overall lifting and lowering technology, "L" hanging wall design and installation, low-input raw material automatic batching system. The company takes "technology, innovation and service" as its purpose to create value for customers. Welcome new and old customers to negotiate: 19805143366.