Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Kiln Engineering Co., Ltd. were established in February 2006 and January 2014 respectively. Is a professional company engaged in glass factory (kiln) design, kiln (equipment) construction and installation and glass production technical services. The company mainly serves the glass factory design of flat glass, photovoltaic calendered glass, electric light source glass, daily-use glass, water glass and ceramic frit production lines, glass engineering installation and construction, firing and baking kiln, commissioning and related technical training, technical services, and professional companies for hot and cold repair of glass kilns.

Because of the different heat sources used in glass melting furnaces, the structural forms are quite different. Such as flame furnace, electric furnace and flame-electric furnace have different structures.

Flame furnace

A furnace that uses coal, heavy oil, gas or natural gas as fuel. The coal-fired crucible kiln is equipped with a fire box. After the coal is burned, semi-gas is produced, which is mixed with secondary air in the flame tube for combustion, and the flame transfers heat in the kiln chamber space. The crucible kiln for fuel oil is equipped with an oil nozzle, and the sprayed oil mist is burned in the fire-breathing tube. There is a small furnace in the pool kiln for burning coal gas, which consists of an air channel, a gas channel, a tongue, a preheating chamber and an outlet. The tank kiln for fuel oil is equipped with a small furnace, which consists of an oil nozzle, an air passage and an outlet. The transverse flame kiln whose flame flow direction is perpendicular to the kiln axis, the longitudinal flame kiln which is consistent with the kiln axis, and the horseshoe flame kiln which is consistent with the kiln axis and rotates in a horseshoe shape. In order to cool the molten glass in the cooling part, a partition device such as a checkered wall, a low arch or a hanging wall is arranged between the melting part and the cooling part, and a liquid hole, a floating brick and a neck are arranged at the bottom to regulate the liquid flow and block the unmelted sand scum, and the molten glass is cooled by a cooling water pipe. The cooling part often communicates with one or more molding parts to distribute the molten glass. Due to different product varieties and molding methods, it can be divided into various forms, such as bottle glass kiln, flat glass kiln, tube drawing kiln, optical glass kiln and ball kiln.

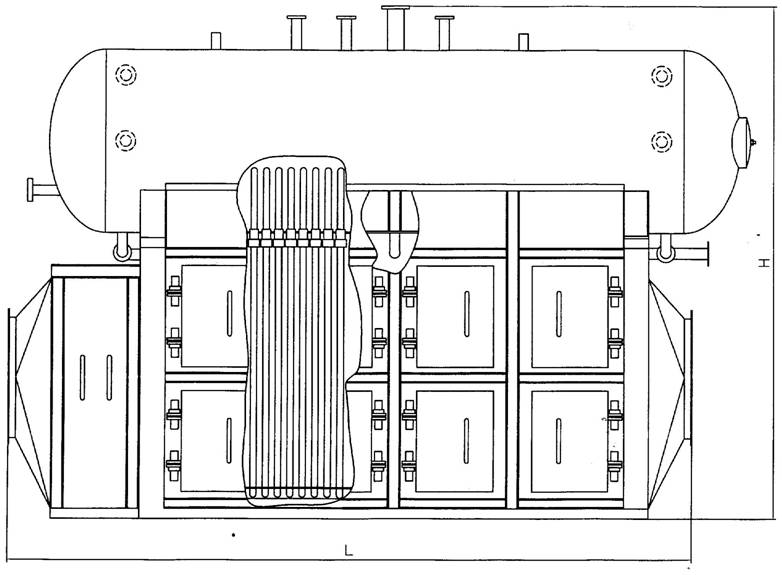

The flame in the flame furnace leaves the furnace chamber with a lot of residual heat, which can be used to heat combustion-supporting air and gas to increase the flame temperature and save fuel. Regenerator or heat exchanger is mainly used to recover waste heat. Fig. 2 is a schematic structural diagram of a continuous tank kiln, that is, a continuous tank kiln that uses a regenerator to recover waste heat. The regenerator uses checker bricks to accumulate part of the heat of flue gas discharged from the kiln chamber. After a certain period of time, the heating operation is reversed, and the checker bricks transfer the accumulated heat to the combustion-supporting air and gas entering the regenerator. Therefore, the regenerator must be set in pairs to make the indirect heating operation continuous. The heat exchanger uses ceramic components or metal pipes as heat transfer body, and continuously transfers the heat of flue gas to combustion-supporting air through the channel wall. Crucible kiln mostly adopts heat exchange type, with simple structure and stable operation. Tank kilns (especially large tank kilns) mostly adopt regenerative type, which has high efficiency and reliability in waste heat recovery, but it needs reversing equipment.

Electric melting furnace

A furnace with electric energy as the heat source. Crucible kiln has two heating modes: resistance heating and induction heating. In crucible kilns for melting optical glass, silicon carbide or molybdenum disilicide resistance heaters are generally installed on the sidewall of the kiln chamber for indirect resistance radiation heating. Some crucible kilns for melting special glass adopt induction heating mode, which is heated by eddy current induced in the kiln and glass liquid. The tank kiln directly uses the glass liquid in the kiln as a heating resistor, and multiple groups and layers of electrodes can be arranged at different depths of the glass liquid to heat the glass liquid, and the temperature system can be controlled by adjusting the power consumption. In this way, the temperature of the space above the glass surface is very low (called the cold top), so the energy is basically consumed in melting glass and cooling the kiln wall, and there is no loss of heat taken away by the flue gas and environmental pollution when the flue gas is discharged, so the heat utilization rate is high, and there is no need to set up a combustion system and a waste heat recovery system. The battery kiln can be controlled automatically, with few managers and good working conditions, but it consumes a lot of power resources. Suitable for melting refractory glass, volatile glass and dark glass. The production capacity of large-scale battery kiln can reach 150t per day.

Flame-electric furnace

Mixed tank kiln with flame heat source as the main source and resistance heating of molten glass as the auxiliary. The operation is similar to the flame pool kiln. In order to increase the melting rate, increase the production capacity and improve the quality of melting, clarification and homogenization of molten glass, electrodes were embedded in the hot spots and charging ports of the flame pool kiln for auxiliary heating, and good results were obtained. The company's professional technicians focus on the design and production technology of float glass, flat-drawn glass, calendered glass and photovoltaic calendered glass production lines, and have carried out bold innovation and transformation from 60t/d to 600t/d, from marten flame and transverse flame furnaces. In recent years, cold repair, baking, thermal insulation and hot repair of large-scale float and rolled glass furnaces are the main projects of the company.

Proprietary technologies of Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Kiln Engineering Co., Ltd.: energy-saving kiln design technology, kiln cold repair breast wall hanging hook brick top replacement, large crown overall lifting and lowering technology, "L" hanging wall design and installation, low-input raw material automatic batching system. The company takes "technology, innovation and service" as its purpose to create value for customers.